Feed extruder machine

Feed floating extruder machine The feed extruder is a processing equipment that extrudes, matures and expands raw materials through mechanical energy, mainly for the production of floating or sinking feed, and has the characteristics of high efficiency, energy saving and multi-function

It adopts self-heating method, no steam system is required, suitable for basic feed processing, simple structure and low maintenance cost

Single screw expander: compact structure, suitable for small and medium-sized feed factories and scientific research institutions

Design advantages: The main components are made of special wear-resistant alloy materials, and their lifespan is 2-3 times longer than conventional materials, while reducing maintenance costs

Processing capability: Floating feed can be maintained in water for more than 2 hours without adhesive, reducing water pollution

Production efficiency: Feed extruder 50-1800kgs/hr, screw self-cleaning function reduces shutdown and cleaning frequency, improves continuous production stability

Technical parameters

| Model | Output(kg/h) | Voltage(V) | Power(kw) | Weight(kg) | Machine size(mm) |

| W-40 | 40-50 | 220/380v | 5.5/7.5 | 300 | 1350*1100*1250 |

| W-50 | 70-80 | 380v | 11 | 330 | 1450*1150*1250 |

| W-60 | 120-150 | 380v | 15 | 360 | 1450*1150*1250 |

| W-70 | 150-200 | 380v | 18.5 | 450 | 1650*1250*1350 |

| W-80 | 200-250 | 380v | 22 | 750 | 1800*1600*1300 |

Application scenarios

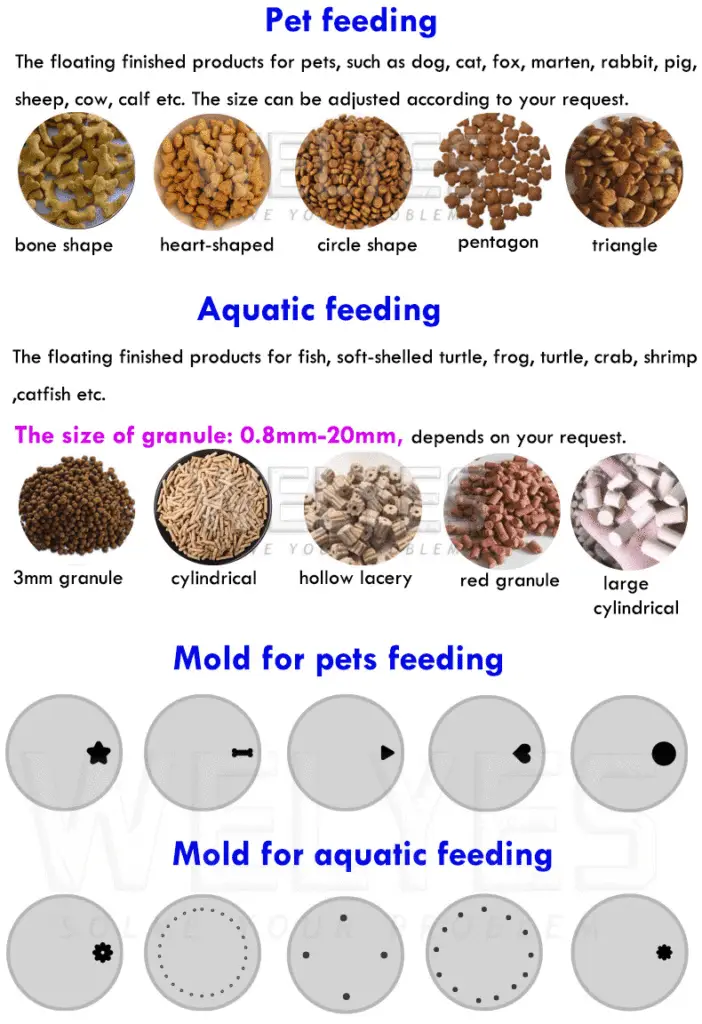

Pet Feed: Suitable for the production of puffed pellets such as dog food and cat food. It has uniform molding and custom shapes to meet the diverse market demand

Aquaculture: produce floating feed (such as bullfrog, sea bass feed) and submerged feed (such as shrimp and crab feed) to reduce the pollution of water quality by residual bait

live and poultry feed: puffed corn, soybean meal and other single raw materials to improve nutritional absorption efficiency and reduce feed waste

Floating Fish Feed Extruder Machine Is Used To Make Different Kinds Of Puffed Food Snacks, The Shapes Can Be Customized. We Can Make Many Kinds Shapes Of Final Products, Also Accept Customize. We Will Send 3 Kinds Of Mould For Free With Our Machines.

The Production Can Produce Different Products According To The Mixing Of Different Raw Materials. The Same Products Can Also Be Produced According To Different Seasonings. It Has Many Models, Flexible Equipment Configuration, A Wide Range Of Raw Materials, A Wide Range Of Products, Simple Operation And So On. By Changing The Mold And Production Process, We Can Produce Various Sandwich Products, Extruded Rice And Fruit, Wheat Roasting, Nutritional Breakfast And Other Products, Which Are Suitable For Various Food Manufacturers