Diesel poultry feed pellet machine

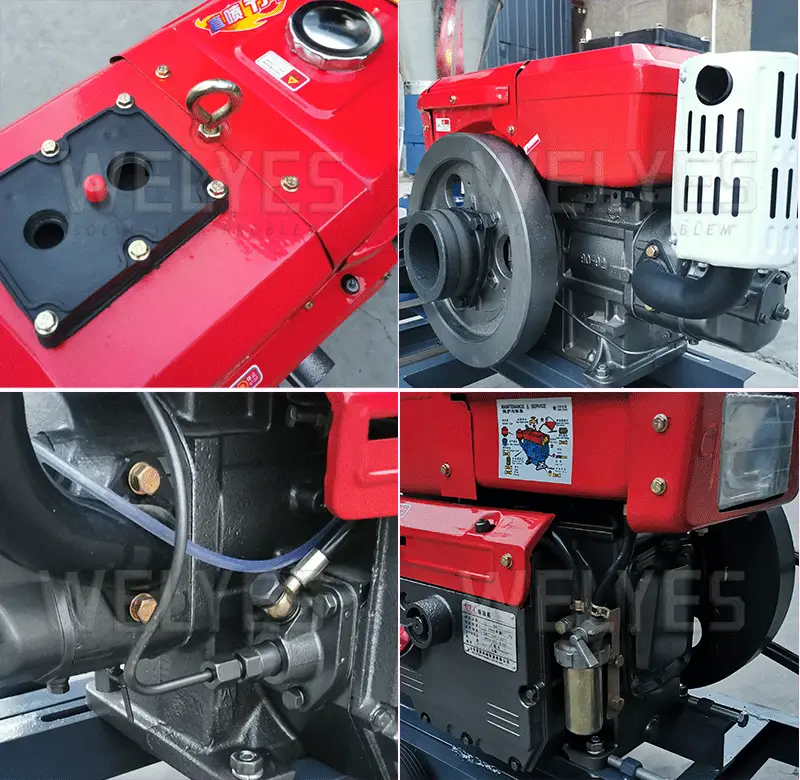

Poultry cow goat chicken feed pellet machine with diesel engine advantages

1. Strong power and adaptability

It is driven by a high-horsepower diesel engine with high torque, which can stably press raw materials such as corn straw and hard straw, especially suitable for high-load continuous operation

No power support is required, suitable for remote areas or outdoor mobile operation scenarios

2. Durable structure and anti-wear

The core components (such as pressure rollers and grinding discs) are made of high-alloy wear-resistant materials, which have a long life and can be used on both sides;

The gearbox and transmission system are scientifically designed, and the bearings are sealed and dust-proof to reduce the failure rate

3. Efficient processing of hard raw materials

Through high temperature and high pressure (70-80 °C) pressing, the lignin is softened, the crude fiber is degraded, and the palatability and digestibility of the feed are improved

The pressing process kills pathogenic bacteria and parasites and reduces the risk of animal disease

4. Support operation in non-electric environment

Solve the problem of no stable power supply in mountainous areas or wild areas to meet the needs of large-scale aquaculture;

Equipped with a one-button start function, easy to operate

5. Reduce the cost of breeding

Waste straw and rattan can be converted into high-nutrient pellet feed to reduce food input (substitution rate of about 27%);

Pellet feed has a low moisture content (about 15%), which is convenient for long-term storage and reduces waste

6. Straw resource utilization

Support corn stalks, rice husks, peanut seedlings and other agricultural wastes directly pressed into feed or fuel pellets

7. High temperature sterilization and nutrition improvement

During the pressing process, the starch is gelatinized at high temperature, the protein is coagulated, and the crude protein content (40.6% increase) and amino acid level are increased

8. Multi-scene adaptation

The mold (aperture 2.5-10mm) can be replaced, and the particle size can be adjusted to adapt to different breeding needs such as livestock and aquatic products