Fish floating pellet machine

floating fish feed extruder machine is pellet feed extruder. cat food, dog food and other pet feed extruder. It can produce a variety of flower shapes, and molds can be customized according to requirements. The product outlet is equipped with a frequency conversion speed rotary cutting device, which can adjust the blade rotation speed at will to control the cutting The speed and length. This product has novel design, high output and stable operation. The main parts are made of alloy materials after heat treatment, and have the characteristics of high wear resistance and long service life

technical parameters

| Model | Output(kg/h) | Voltage(V) | Power(kw) | Weight(kg) | Machine size(mm) |

| W-40 | 40-50 | 220/380v | 5.5/7.5 | 300 | 1350*1100*1250 |

| W-50 | 70-80 | 380v | 11 | 330 | 1450*1150*1250 |

| W-60 | 120-150 | 380v | 15 | 360 | 1450*1150*1250 |

| W-70 | 150-200 | 380v | 18.5 | 450 | 1650*1250*1350 |

| W-80 | 200-250 | 380v | 22 | 750 | 1800*1600*1300 |

feed extruder is a single-screw extruder extruder, mainly used for the expansion of various livestock, poultry, pets and aquatic feeds. It can be used to extrude a single raw material or as the pretreatment of raw materials in the production of vegetable fats and animal waste. deal with. W type is a small and medium-sized dry extruder in the series. Its main features are:

1. To adapt to different production requirements, large and medium-sized feed factories can be used for raw material processing or special feed production. Such as the detoxification treatment of expanded full-fat soybeans, expanded corn, cotton meal (or rapeseed meal) or expanded pet feed, aquatic feed, fox feed or other special feeds. Small feed factories or large and medium-sized farms can also use this extruder as the main equipment to produce full-price extruded feed

2. Adapt to different materials and different production conditions. This machine is equipped with an automatic speed-regulating feeder, and the feeding amount can be changed according to the situation. The extrusion screw is a sleeve type combined structure, and the screw sleeve adopts an inner cylinder structure. According to different expansion requirements, the corresponding extrusion screw group can be flexibly formed, and then equipped with different outlet parts, it can adapt to different processing conditions

different Molds for feed extruder machine

Advantages of extruder machine for fish or pets

Loading inlet: extended inlet of the machine easy to feed, screw winch, T-type mixing paddle, speed feeding device. Automatic uniform feed to prevent the machine from choking.

2. Heating device: with the lengthening screw sleeve design, the external extension heating plate increasing the heating area and improve the rate of heating, promoting the curing effect of material; the material of the sleeve is alloy steel with carburizing treatment of high temperature, making the srew has a good characteristic of wear-resistance and long lifetime.

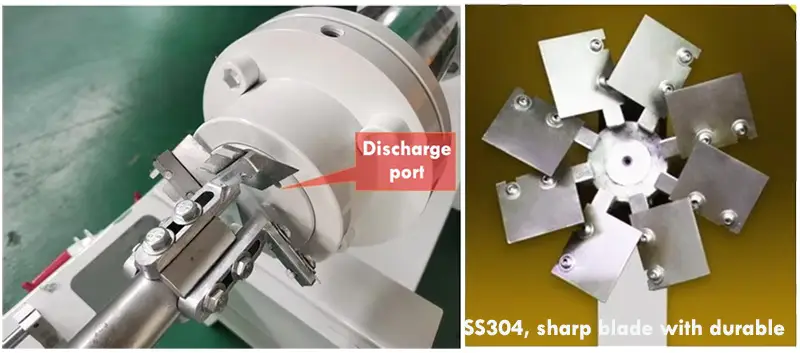

3. Cutting device: sliding cutter, independent cutter motor, power stability, adjustable cutter clearance, discharge outlet equipped with frequency control rotary cutting device, can arbitrarily adjust the blade rotation speed, to control the cutting speed and length. International advanced grain cutting structure, the use of soft knife fit form, to achive stepless speed change, can be arbitrarily cut into the required length of the product, not easy to produce burrs