Harvesting forestry trailer with timber crane

our welyes Forest ATV Wood Log Trailer with Crane can handle multiple materials such as logs, wood, and straw, as well as cotton, sugarcane, bales, scrap metals, pipes, and other materials, meeting diverse operation requirements.

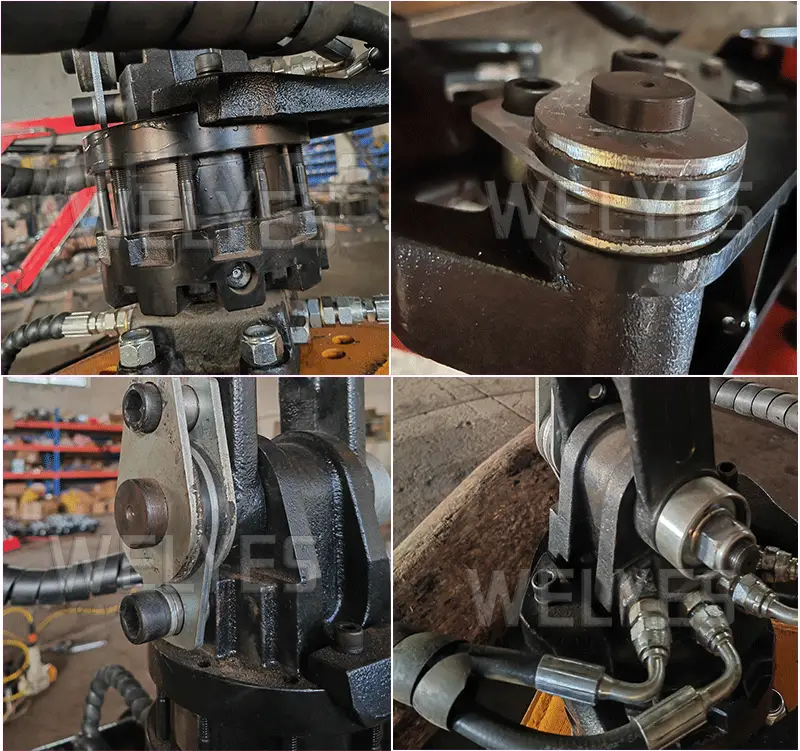

The hydraulic gripper design is flexible, allowing for precise control of the clamping force and reducing damage to the material surface. It is suitable for loading and unloading high-value wood, achieving efficient loading, unloading and stacking. Below share the advantages, please check.

firstly, telescopic arms:At timber harvesting sites, telescopic boom log loaders can be utilized to grasp felled logs, consolidate them into piles, and transfer them onto transport vehicles. Whether in coniferous or broadleaf forests, these machines adapt flexibly to various stacking positions and vehicle heights with their versatile operation. In addition, When the sugarcane is ripe for harvesting, the sugarcane grabber (a telescopic boom grabber equipped with specific claws) can work along the ridges of the sugarcane field, grabbing one or more ridges of sugarcane and stacking them neatly onto the transport vehicle, reducing the intensity and workload of manual handling. For sugarcane fields with irregular terrain, the sugarcane grabber can also work flexibly by adjusting the angle and length of the telescopic boom.

Before sugarcane planting, it can also be used to grab and carry sugarcane seeds, and assist in the sowing layout; secondly, Heavy-duty base: the loading weight is more than small one. Also the pipe is more bolded and length is more largeger than standard type, more stable and strong when it works. About length of pipe, heavy tyeps is 1800mm, standard type is 1400mm. In addtion, it’s hard to break since the method of processing is Integral molding cast parts, more strong with large bearing and Heavy-Duty Construction Built to withstand the harsh conditions of logging environments, the crane is constructed from durable materials that ensure longevity and reliability. Its heavy-duty design can handle substantial weights, making it suitable for lifting large timber logs with ease. Thirdly, Vertical column is An important structural component that supports the entire robotic arm and gripping device. this heavy type designed with Thickening material, Enhance structural strength: Bending and torsional resistance as well as Stress dispersion, Improved stability and accuracy: Vibration suppression, The stout column can effectively absorb the vibration generated by the movement of the robotic arm (especially the impact force at the moment of grabbing), reduce the shaking of the operation, and ensure the accuracy of grasping positioning, Anti-lateral deflection: When working in complex terrain (such as slopes and muddy ground), the thickened column can resist the fuselage deflection caused by lateral force and reduce the risk of overturning. Extended service life: Abrasion and corrosion resistance: By increasing the wall thickness (usually from 10mm to 15-20mm), the anti-wear and anti-rust period of the column under harsh environments (e.g., high humidity in the rainforest, lumber dust) can be extended. Fatigue Life Improvement: The bold design increases the fatigue strength of critical welded joints, such as the column and chassis joints, by more than 30%, extending the equipment overhaul interval to more than 10,000 hours

At last, its Control valve group: The multi-way valve controls the flow direction of the hydraulic oil, enabling independent or combined operations such as opening and closing the gripper, rotation, and lifting. The joystick control system of the forestry logging grapple crane provides intuitive operation, allowing the crane to move precisely for efficient loading and positioning of timber. This user-friendly interface allows for quick adjustments and responsive control, which reduces operator fatigue and increases overall productivity.

Besides, There’s Remote Winch Design To Enhance Highten The Dragging Strength. All The Winches Are Remote Type In Order To Improve Working Efficiency, Save Time And Reduce Operator Risk, More Safe. As For Remote Control Winch,Its Power Source From Electric Motor And Is Remotely Controlled Through Controller. Also It Can Adjust The Rolling Speed Accordingly And Support Multi-Directional Remote Control, Which Is More Suitable For Operations That Require Fine Control.

Application Scenarios

1. Forestry Operations: The Common Use Of Log Grabber In Forestry Is To Transport Wood, Which Can Quickly And Accurately Grab Wood And Move It To The Designated Location, Which Greatly Improves The Efficiency Of Wood Processing. In Addition, The Wood Grabber Can Also Be Used For Tree Pruning And Felling

2. Agriculture: In The Agricultural Field, The Wood Grabber Can Be Used To Process Crops, Such As Straw, Pasture, Etc., Grabbing Them From The Field And Stacking Them For Subsequent Processing And Utilization. In Addition, The Log Grabber Can Also Be Used For Farmland Transformation Work, Such As Digging Ditches, Leveling Land, Etc

4. Industrial & Manufacturing: In The Field Of Industrial And Manufacturing Industry, Log Grabbers Are Widely Used In The Handling Of Various Materials, Including Wood, Sand, Coal, Steel And Other Heavy Materials. It Can Also Be Used As Auxiliary Equipment On The Production Line To Grab And Place Products, Improving Production Efficiency

| Model | TC420 | TC470L | TC550L | TC600L | TC650L | TC700L | TC750L | TC850L | TC780L |

| Arm length (m) | 4.2 | 4.7 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8.5 | 7.8 |

| Rotary torque (kn.m) | 11 | 11 | 11 | 11 | 19 | 19 | 19 | 19 | 18 |

| Rotation angle | 380° (right 190°, left 190°) | 380° (right 190°, left 190°) | 380° (right 190°, left 190°) | 380° (right 190°, left 190°) | 380° (right 190°, left 190°) | 380° (right 190°, left 190°) | 380° (right 190°, left 190°) | 380° (right 190°, left 190°) | 380° (right 190°, left 190°) |

| Number of rotating cylinders(piece) | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Lifting force at 4 m (kg) | 580 | 540 | 770 | 780 | 2000 | 1900 | 2000 | 1500 | 1880 |

| Lifting force at full length (kg) | 520 | 480 | 540 | 500 | 1000 | 830 | 760 | 650 | 720 |

| Grab swing brake from side to side | yes | yes | yes | yes | yes | yes | yes | yes | yes |

| Grab swing brake back and forth | yes | yes | yes | yes | yes | yes | yes | yes | yes |

| Telescopic boom structure | no | yes (one section telescopic arm about 850 mm) | yes (one section telescopic arm about 1000 mm) | yes (one section telescopic arm about 1000mm) | yes (two section telescopic arm about 1400mm) | yes (two section telescopic arm about 1600mm) | yes (two section telescopic arm about 1980mm) | yes (two section telescopic arm) | yes (two section telescopic arm about 2500mm) |

| Boom 360° rotary valve | 1pcs | 1pcs | 1pcs | 1pcs | 1pcs | 1pcs | 1 pcs | 1pcs | 1pcs |

| One-way throttle valve for 360° rotation of boom | 2pcs | 2pcs | 2pcs | 2pcs | 2pcs | 2pcs | 2 pcs | 2pcs | 2pcs |

| Balance valve | 1pcs | 1pcs | 1pcs | 1pcs | 1pcs | 1pcs | 1 pcs | 1pcs | 1pcs |

| Recommended hydraulic oil flow (l/min) | 30-45 | 30-45 | 40-50 | 40-50 | 45-55 | 45-70 | 45-70 | 45-70 | 45-70 |

| Working pressure (mpa) | 20 | 20 | 20 | 20 | 20 | 22 | 22 | 22 | 22 |

| Standard rotary motor | GR-10 (1T pin shaft) | GR-30 | GR-30 | GR-30F (3t flange type) | GR-30F (3T flange type) | GR-30F (3T flange type) | GR-40F (4T flange type) | GR-40F (4T flange type) | GR-30F (3T flange type) |

| The standard grab | TG08 (max opening size 800mm) | TG18 (max opening size 1080mm) | TG20 (max opening size 1260mm) | TG20 (max opening size 1260mm) | TG20 (max opening size 1260mm) | TG26 (max opening size 1470mm) | TG26 (max opening size 1470mm) | TG26 (max opening size 1470mm) | TG26 (max opening size1470mm) |

| Total weight (support leg&valve excluded) | 680kgs | 708kgs | 774kgs | 817kgs | 1093kgs | 1152kgs | 1232kgs | 1556 | 1214kgs |

| Surface coating | Spray powder-coated (standard color: big and small arms, column base, fixture teeth are red, others are black; OEM color accepted) | ||||||||

| Hydraulic tubing | The oil inlet diameter is 16and the oil return diameter is 19, which is matched with G3 / 4 “quick connector. The forearm of main boom is equipped with external iron tubing | ||||||||

| Weight (kgs) | 196 | 196 | 196 | 196 | 213 | 213 | 213 | 213 | |

| hyrdraulic system | Hydraulic system with hydraulic lock, prevent oil leakage in the hydraulic circuit, resulting in insufficient support rigidity, or prevent the malfunction of the hydraulic cylinder | ||||||||

As for the tractor trailer, it has Transportation function: In rural or mountainous areas with poor road conditions, it can replace trucks to complete short-distance and efficient transportation, and adapt to complex terrains such as muddy ground and slopes. Open design, load capacity ranging from 3 to 14 tons, available for your selection. And its towing function: It connects to the trailer through towing

| Model | TR30 | TR60 | TR80 | TR100 | TR120 | TR140 |

| Air brake system | no | no | yes (four wheels with brake disc 1061 type) | yes (four wheels with brake disc 1061 type) | yes (four wheels with brake disc 1061 type) | yes (four wheels with brake disc 1061 type) |

| Rear light for warning | no | no | yes (more safe at environment with poor visibility) | yes (more safe at environment with poor visibility) | yes (more safe at environment with poor visibility) | yes (more safe at environment with poor visibility) |

| Loading capacity (kgs) | 3,000 | 6,000 | 8,000 | 10,000 | 12,000 | 14,000 |

| Matched tractor power (hp) | 30-40 | 40-50 | 60-80 | 80-100 | 80-100 | 100-150hp |

| Loading area (m3) | 0.9 | 2.0 | 2.3 | 2.6 | 2.8 | 3.0 |

| Beam size (mm) | 1600*800*70 | 1600*800*70 | 1800*1000*70 | 1800*1000*70 | 2000*1000*80 | |

| Total length (mm) | 4,100 | 5,200 | 5,900 | 6,000 | 6,080 | 6,290 |

| Trailer loading length (mm) | 2,850 | 3,100 | 3,600 | 3,850 | 3,900 | 4,030 |

| Total width (mm) | 1,460 | 2,060 | 2,200 | 2,270 | 2,350 | 2,480 |

| Tyre model | 300/60-12 | 400/60-15.5 | 400/60-15.5 | 400/60-15.5 | 500/50-17 | 500/50-17 |

| Quantity of tyre (pcs) | 4 | 4 | 4 | 4 | 4 | 4 |

| Traction swing | si y angel de 38° | no | no | 40° | 40° | 40° |

| Extension beam | yes (about 900mm extension) | |||||

| Blocking pipe (pcs) | 4 | 6 | 8 | 8 | 8 | 10 (2pcs More Than Standard Model due to the extension beam)) |

Air Brake System Of Trailer: Due To Their Strong Braking Power And Fast Reaction Time, Air Brake Systems Are Commonly Used In Large Trucks, Buses And Heavy Machinery. These Vehicles Require More Braking Power And Faster Reaction Times To Ensure Safety. As For The Oil Brake, Oil Brake : Due To Its Simple Structure And Soft Response, The Oil Brake System Is More Suitable For Small Cars And SUVs. Due To Their Small Size And Light Weight, These Vehicles Do Not Require Much Braking Force, So The Oil Brake System Is More Suitable. 4WD System Of Trailer/Tow-Behind It Can Improve The Traction And Passability Of The Vehicle And Is Suitable For Various Road Conditions.

The Four-Wheel Drive Performs Better On Snow Slopes, And The Power Covers All Four Wheels To Avoid Power Interruption Caused By The Slippage Of A Single Drive Wheel; It Can Also Maintain Continuous Power Output On Rough And Muddy Roads, Avoid Power Loss Caused By Single-Wheel Skidding, And Have Strong Adaptability To Complex Road Conditions. Tail Light Of The Tow-Behind And Tractor Trailer Core Functions 1. Signal Warning Brake Signal: The Red Brake Light Illuminates When Braking, Prompting The Vehicle Behind To Slow Down Or Stop, Preventing Rear-End Collision. Turning Instructions: The Yellow Turn Signal Flashes To Indicate The Direction Of The Trailer, Ensuring That Other Traffic Participants Avoid It In Time When Changing Lanes Or Turning. 3. Reverse Lighting: The White Reversing Light Provides Rear Lighting When Reversing, And Also Warns Surrounding Vehicles And Pedestrians To Pay Attention To The Trailer’s Movement Trajectory. 2. Visibility Improvement Contour Positioning: The Red Contour Light Displays The Trailer Profile At Night Or In Low Light Environments, Making It Easier For Other Vehicles To Judge Their Size And Position. Fog Day Warning: The Rear Fog Lights Enhance Penetration In Rainy And Fog Weather, Improving The Visibility Of Trailers In Harsh Environments

About the telescopic beam expansion part, its advantage as below: 1. Length adjustment and adaptability expansion The telescopic beam adjusts the trailer length through a mechanical telescopic structure to match the transportation needs of goods of different sizes (such as extra-long wood) and ensure the stability of the goods during transportation. 2. Enhance the overall structural bearing capacity By adjusting the unfolded length of the telescopic beam, the load distribution is optimized. For example, shortening the beam can increase the local bearing strength, and extending it can adapt to larger volumes of goods, similar to the load control principle of the wood grabber boom. 3. Terrain adaptability optimization When driving on complex roads (such as farmland and ramps), the adjustment function of the telescopic beam can balance the center of gravity of the trailer, prevent cargo displacement or structural deformation caused by bumps, and improve driving stability